Products

Fine Bar Tech’s Products

Fine Bar Tech has developed original technologies on the fields of manufacturing precise rolls, repairing rolls, manufacturing various machines, polishing and mirror finishing, hard chrome plating, and designing and manufacturing various jigs. Since Fine Bar Tech assume to prove worthy of our customers’ trust, we has sedulously improved our technologies to provide high quality products to our customers.

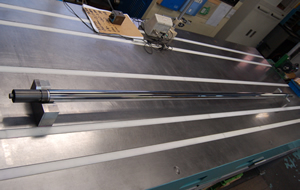

φ40×1800×2015L

Work roll for tension leveling

A cartridge attached.

![]() Circularity tolerance: 0.001mm or less

Circularity tolerance: 0.001mm or less

![]() Cylindricality tolerance: 0.005mm

Cylindricality tolerance: 0.005mm

![]() Run-out tolerance of the circumference: 0.010mm

Run-out tolerance of the circumference: 0.010mm

Hard chrome plating: 40±10μm

Surface-roughness: Ra0.05 or less

φ100×1800L

Work roll for tension leveling

A cartridge attached.

![]() Circularity tolerance: 0.001mm or less

Circularity tolerance: 0.001mm or less

![]() Cylindricality tolerance: 0.005mm

Cylindricality tolerance: 0.005mm

![]() Run-out tolerance of the circumference: 0.010mm

Run-out tolerance of the circumference: 0.010mm

Hard chrome plating: 40±10μm

Surface-roughness: Ra0.05 or less

φ55×1466L

Work roll for roll leveling

![]() Circularity tolerance: 0.001mm

Circularity tolerance: 0.001mm

![]() Cylindricality tolerance: 0.005mm

Cylindricality tolerance: 0.005mm

![]() Run-out tolerance of the circumference: 0.010mm

Run-out tolerance of the circumference: 0.010mm

Pair-difference: 10μm

Surface-roughness: Ra0.2 or less

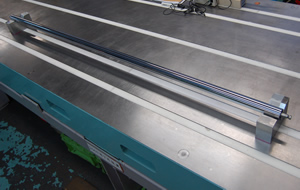

φ32×1480L

Intermediate roll for tension leveling

A cartridge attached.

![]() Circularity tolerance: 0.001mm or less

Circularity tolerance: 0.001mm or less

![]() Cylindricality tolerance: 0.005mm

Cylindricality tolerance: 0.005mm

![]() Run-out tolerance of the circumference: 0.010mm

Run-out tolerance of the circumference: 0.010mm

Surface-roughness: Ra0.05 or less

φ75×155L

Backup roll for tension leveling

A bearing outer ring attached with to the axis

![]() Circularity tolerance: 0.006mm or less

Circularity tolerance: 0.006mm or less

![]() Cylindricality tolerance: 0.006mm or less

Cylindricality tolerance: 0.006mm or less

![]() Run-out tolerance of the circumference: 0.010mm or less

Run-out tolerance of the circumference: 0.010mm or less

Pair-difference: 0.010 or less (at the dimension of H)

Surface-roughness: 0.8S or less

φ95×100L

Backup roll for roller leveling

![]() Circularity tolerance: 0.010mm

Circularity tolerance: 0.010mm

![]() Cylindricality tolerance: 0.015mm

Cylindricality tolerance: 0.015mm

![]() Run-out tolerance of the circumference: 0.010mm (On the basis by the hole)

Run-out tolerance of the circumference: 0.010mm (On the basis by the hole)

Pair-difference: 0.010mm

Surface-roughness: 0.6S or less

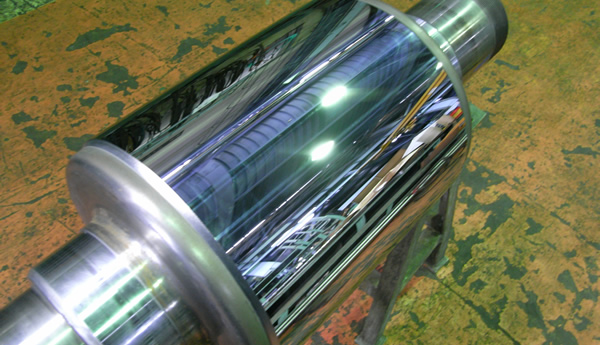

Roll for metal rolling φ400×500W×1000L

![]() Circularity tolerance: 0.005mm

Circularity tolerance: 0.005mm

![]() Cylindricality tolerance: 0.01mm

Cylindricality tolerance: 0.01mm

![]() Run-out tolerance of the circumference: 0.01mm

Run-out tolerance of the circumference: 0.01mm

Surface-roughness: Ra0.01 or less

Super mirror finished

Hard chrome plating: 150μm

Shot roll φ135×500L

Mid-air type

A macrophotography of the surface of the roll.

![]() Circularity tolerance: 0.01mm

Circularity tolerance: 0.01mm

![]() Cylindricality tolerance: 0.01mm

Cylindricality tolerance: 0.01mm

![]() Run-out tolerance of the circumference: 0.01mm on the basis by the axis (the tolerance).

Run-out tolerance of the circumference: 0.01mm on the basis by the axis (the tolerance).

Surface-roughness: Ra2.2

Hard chrome plating: 20-30μm

Static balance: 35g

φ40×1250W×1316L

A macrophotography of the surface of the roll.

A macrophotography of the surface of the roll.

A macrophotography of the surface of the roll.

![]() Circularity tolerance: 0.002mm

Circularity tolerance: 0.002mm

![]() Cylindricality tolerance: 0.01mm

Cylindricality tolerance: 0.01mm

![]() Run-out tolerance of the circumference: 0.018mm

Run-out tolerance of the circumference: 0.018mm

Surface-roughness: Ra2.5/Rz14.0

Hard chrome plating: 65±5μm

High hardness hard chrome plating (HEEF25)

About the measurement of circularity

The conventional precise measurements of circularity, such as the round test or the Talyrond, could not measure objects with a length over 1000mm, like rolls for leveling, since the length of object that could be measured with those tests was limited to about 500mm long. Recently, however, we make it possible to measure circularity of rolls without reference to the length of the rolls at the same level as the conventional precise measurements of circularity.

About the mentions

SUJ-2: up to 5mm expanding

SC material: up to 3mm expanding

SCM material: up to 3mm expanding

Hardening: the hardness is around HS90UP

The hardness of the Hard chrome plating: around HV1000